Sara Cumming is the Jewelry Production and Social Media Coordinator at Kimberfire – a brilliant way to buy diamond engagement rings, fine diamond jewelry, and loose diamonds in Toronto, ON and across Canada. She holds a Bachelor of Fine Art from York University and a Diploma in Jewelry Arts from George Brown College. She is skilled in jewelry design using CAD software, as well as traditional goldsmith techniques. When she is not immersing herself in all things jewelry, Sara is a dog mom to Barley, her beagle mix rescue dog who loves a good tummy rub.

Our Custom Engagement Ring Manufacturing Process

Every one of us has admired the flawless beauty of an engagement ring, whether lined up in rows in a glass case in a store, on the hand of a friend or family member, or maybe even on your very own finger. But while we are all familiar with the finished ring, not everyone knows what goes into making it. In fact one of the most asked questions I receive from friends is “how is the ring made?”. In this article I take you behind the scenes to follow a Kimberfire custom engagement ring from concept to creation.

What Do Engagement Rings and Computers Have in Common?

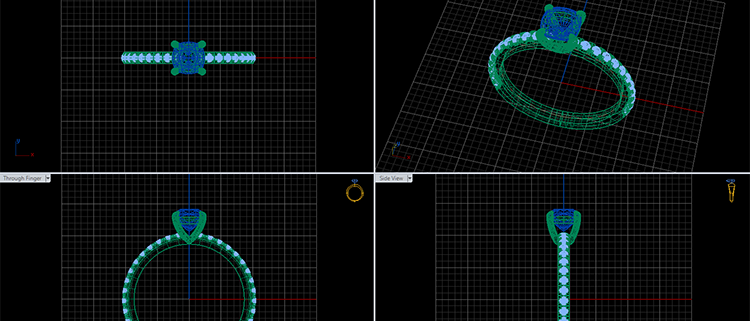

Our journey begins with the jewelry designer. Our designer works closely to the specifications for the client’s custom piece – taking all the features our sales team has discussed with the client and the details of the diamonds being set, our designer brings the vision to life. We exclusively use computer aided design (CAD) programs to create 3D models of our rings. Once the 3D rendering is approved by our client, we then create the model in wax using a 3D printer. The wax piece is an exact model of the ring that will be cast into metal. Before the invention of CAD programs a jeweller would either hand carve the ring out of a block of wax or fabricate the metal by hand. There are still jewellers today who use the traditional goldsmith techniques but they are becoming less common with the growth of technology.

Gold, Platinum… Whichever You Like!

Next we cast the wax model into metal. This is done by using a method called investment casting. The wax model is set up inside a watertight flask. The investment powder, which is a plaster which has been formulated to withstand very high temperatures, is mixed with water and poured into the flask to completely cover the wax model. A few hours later the investment has hardened into a solid plaster. This flask is then put into a kiln and heated to 1250 degrees Fahrenheit, the temperature at which wax melts but investment doesn’t. There is now a perfect mold of the ring in the flask where the wax model used to be, and the flask is put into a centrifugal casting machine or a vacuum casting machine. These machines are necessary because they use force to make sure the metal will fill the entire mold. The metal to be used is then broken up into tiny pieces, placed in a crucible and heated with a torch until it becomes molten. The liquid metal is then poured into the flask and the casting machine quickly started. When the machine stops, the flask is removed and plunged into a bucket of water, which washes all the investment away, leaving only the metal ring. The ring still needs to be cleaned up as it is completely covered in a rough ‘casting skin’, which the goldsmith will remove to bring the metal to a high polish.

Time for Some Bling

Now the Ring is ready for its diamonds! Our gem setter collects the ring and any stones which are to be set into the metal. Our setter uses various techniques and styles to provide different looks. Most of our setting is done under a microscope, especially for the popular pave or micro pave styles which use very small diamonds, ensuring secure setting of the centre diamond or gemstone and very close and fine setting of the small diamonds. Once all the stones are set and secure the ring goes back to the goldsmith for a final polish and cleaning.

Ready for Delivery

The ring is now complete, but not yet ready for game time! The ring is first sent to a third party appraiser who documents all the details of the ring and determines its market or replacement value. This appraisal is necessary if our client is planning on insuring their ring.

The rings journey concludes with being tucked into a little velvet box. Our clients can then pickup their engagement rings in Toronto, or we can ship to a secure pickup location near their home.

The ring is now ready for its most important moment, when it is slipped onto a lucky someone’s finger as a symbol of love and commitment.

About Kimberfire

A brilliant way to buy high-quality engagement rings, diamonds, and jewelry. View and inspect your carefully selected diamond virtually (via Zoom), or in our offices in Toronto, Canada. We ship worldwide.

Leave a Reply

Want to join the discussion?

Feel free to contribute!